Common Paint Defects

Gelling

Skinning

Settling

Prolonged Tackiness

Rising Damp

Foaming / Cratering

Improper Induction of Epoxy

Mud Cracking

Fungal Growth

Algal Growth

Saponification

Poor Galvanized Metal Adhesion

Chalking

Efflorescence / Mootling

Paint Incompatibility

Sagging

Peeling

Blistering

Cracking/Flaking

Gelling

Decreasing viscosity caused by bacterial degradation of the protein binder or other thickening agents. This is often accompanied by an offensive odour. CAUSES: Use of

Skinning

Formation of a layer of skin on the surface of the paint or the container. CAUSES: Use of non-airtight containerLack of anti-skinning agentStorage under excessively

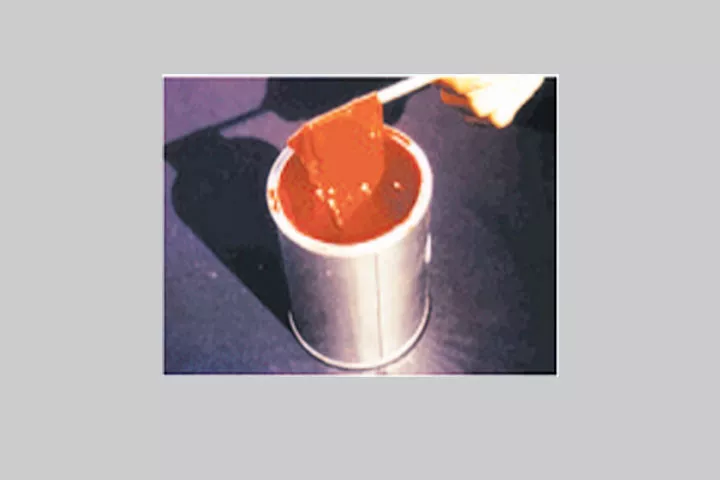

Settling

Settlement of pigment to the bottom and failure to re-disperse. CAUSES: Insufficient stirring during storage. Storage for long duration or under excessively warm condition. Excessive

Prolonged Tackiness

A coat of paint is dry when it ceases to be “tacky” to the touch. Prolonged tackiness indicates excessively slow drying. This may be caused

Rising Damp

Rising damp actually describes the movement of moisture upward through permeable building materials by capillary action. It becomes a problem if the moisture penetrates vulnerable

Foaming / Cratering

Formation of bubbles or foam and resulting small, round concave depressions. When bubbles break in a paint film, during paint application and drying. Possible Causes:

Improper Induction of Epoxy

Epoxy is a two-part system, consisting of a Base and converter. Improper Induction will result in difference in color, soft film, peeling, difference in gloss,

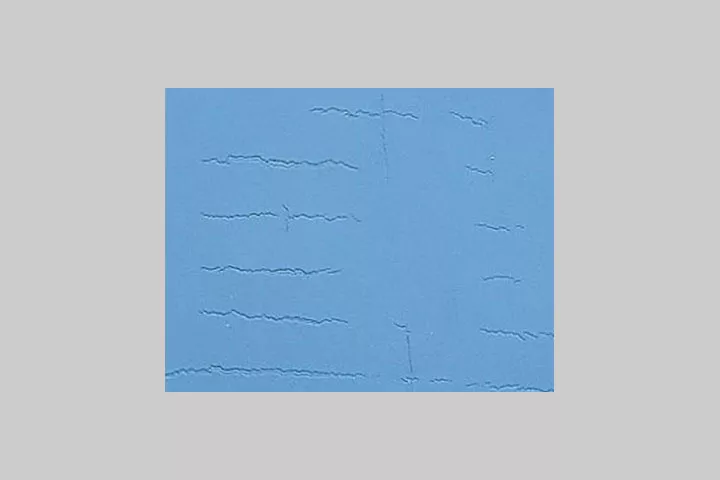

Mud Cracking

Deep, irregular cracks resemble dried mud in dry paint film. Possible Cause: Paint is applied too thickly, usually over a porous surface. Paint applied too

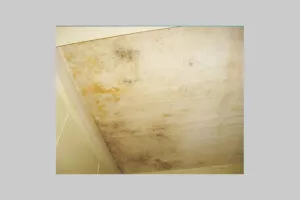

Fungal Growth

Fungus growth can appear with high humidity of surroundings or damp substrate or high moisture content. Fungus is commonly found on internal wall surfaces of

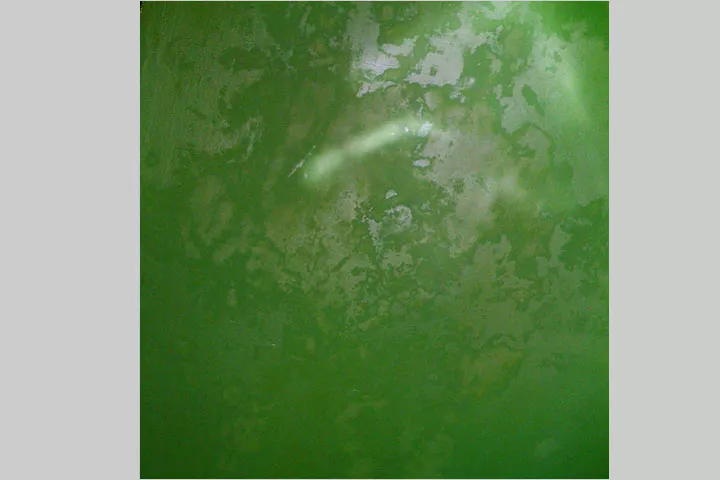

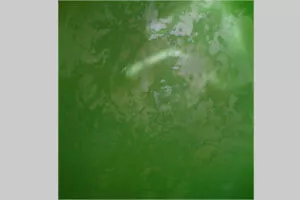

Algal Growth

The coating surface shows a green growth, usually on north facing timbers. Possible Cause: Plants, bushes and trees in close proximity to coating system. High

Saponification

Alkyd and oil-based paints react and saponify with alkalis present in new masonry to form water-soluble soaps. The paint film turned into soap, becomes soft,

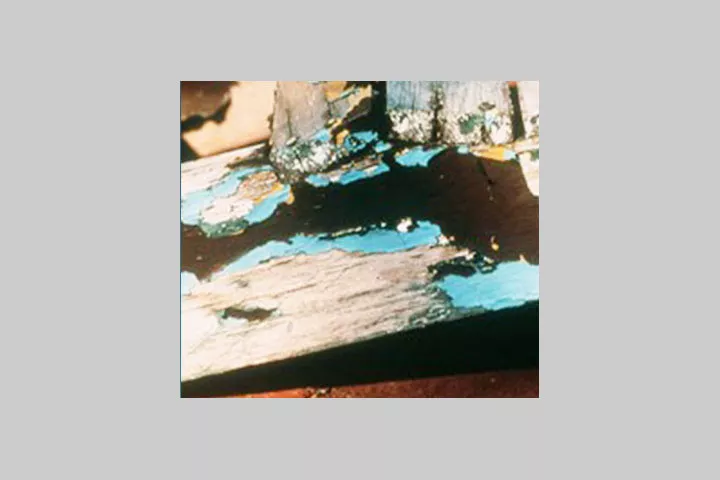

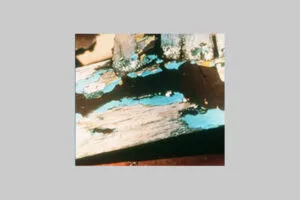

Poor Galvanized Metal Adhesion

Paint that has lost its adhesion to a galvanised metal substrate. Possible Cause: Improper surface preparation, such as inedquate rust removal. Failure to remove the

Chalking

Formation of fine powder on the surface of the film during weathering, which can cause colour fading. Although some degree of chalking is a normal,

Efflorescence / Mootling

Crusty white salt deposits, leached from martor or masonry as water passes through it. Possible Cause: Painting over insufficiently cured concrete. Excess moisture escaping through

Paint Incompatibility

Loss of adhesion where many old coats of alkyd or oil base paint received a latex top coat. Possible Cause: Use of water base latex

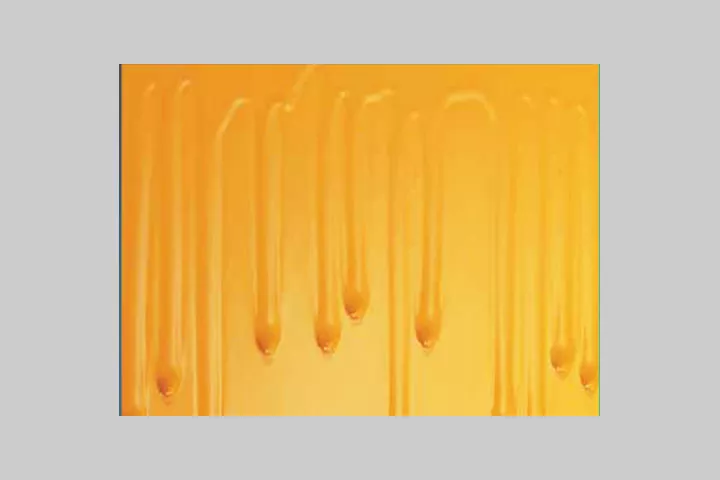

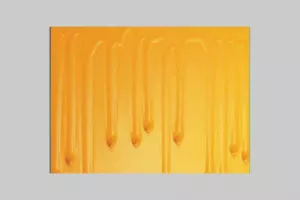

Sagging

Downward “dropping” movement of the paint film immediately after application resulting in an uneven coating. Possible Cause: Application of a heavy coat of paint. Application

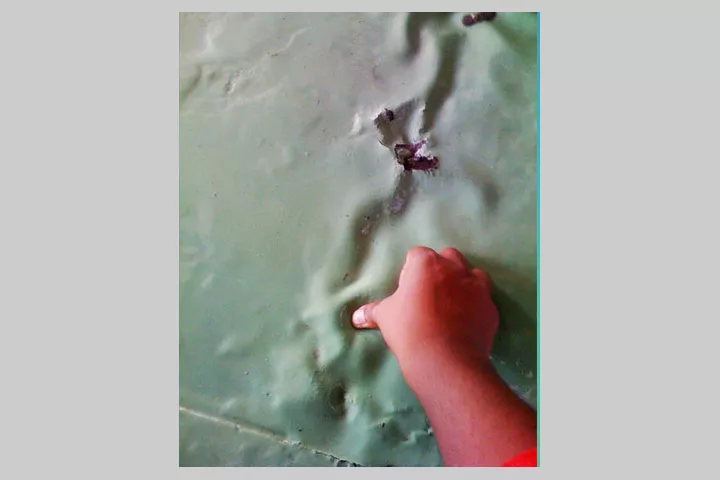

Peeling

Loss of paint due to poor adhesion. Where there is a primer and top coat, or multiple coats of paint, peeling may involve some or

Blistering

Bubbles resulting from localized loss of adhesion and lifting of the paint film from the underlying surface. Possible Causes: Painting a warm surface in direct

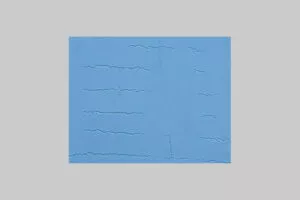

Cracking/Flaking

The splitting of a dry paint film through at least one coat as a result of aging, which ultimately will lead to complete failure of